Materials Engineer

At Sydub Engineering Firm, every solution begins with the expertise of a Materials Engineer. Our work isn’t just about selecting the right materials, it’s about applying science, creativity, and precision to solve real-world challenges. Our team blends innovative thinking with advanced technologies to design systems that improve performance, increase reliability, and turn complex ideas into practical realities. From high performance components to durable energy solutions, we are committed to delivering engineering results that empower industries and improve lives. At Sydub, we don’t just work with materials, we engineer possibilities.

Mechanical Projects

Material Selection

Corrosion Assessment

Failure Analysis

Property Testing

Metallurgical Testing

Additive Support

Polymer Evaluation

All Projects

The Process:

-

1: Consult

We start with an in-depth discussion to understand your needs from our Materials Engineer team, challenges, and goals. Our team works closely with you to define the project scope and outline requirements.

-

2: Design

Our Materials Engineer team creates a custom solution to solve your problem, outlining technical requirements, design concepts, and timelines. We ensure the project aligns with your vision and objectives.

-

3: Develop

Using the latest technologies our Materials Engineer team develops the system with attention to quality, performance, and scalability. Regular updates and feedback ensure we're on the right track.

-

4: Testing

We conduct thorough testing to ensure seamless functionality, performance, and security across all platforms. Our team identifies and resolves issues, optimizing the system for a flawless Production.

-

5: Deploy

Once tested, we deploy the solution and ensure smooth integration with existing systems. Our engineers oversee the deployment to ensure everything runs efficiently, securely, and scales as needed.

-

6: Support

After deployment, our Materials Engineer team provides ongoing support to address updates or issues. We're here to ensure your System remains reliable as possible and future-proof.

Material Selection:

Choosing the right material can make or break a product. From strength and weight to environmental resistance and cost, many factors come into play. A Materials Engineer brings the technical insight needed to balance performance with manufacturability, helping clients confidently select materials that meet both functional and regulatory requirements across various industries.

Failure Analysis:

When a product fails in the field, fast and accurate diagnosis is essential. Leveraging techniques like microscopy, spectroscopy, and stress testing, failure analysis uncovers the root cause—whether it's fatigue, corrosion, or contamination. This investigative work is led by a Materials Engineer, whose findings guide design improvements, legal defense, or insurance claims.

Metallurgical Testing:

A deep understanding of metallic structures is critical in applications ranging from aerospace to heavy industry. Through services such as grain structure evaluation, heat treatment verification, and mechanical testing, Materials Engineers help ensure that metals meet stringent standards and perform reliably under demanding conditions.

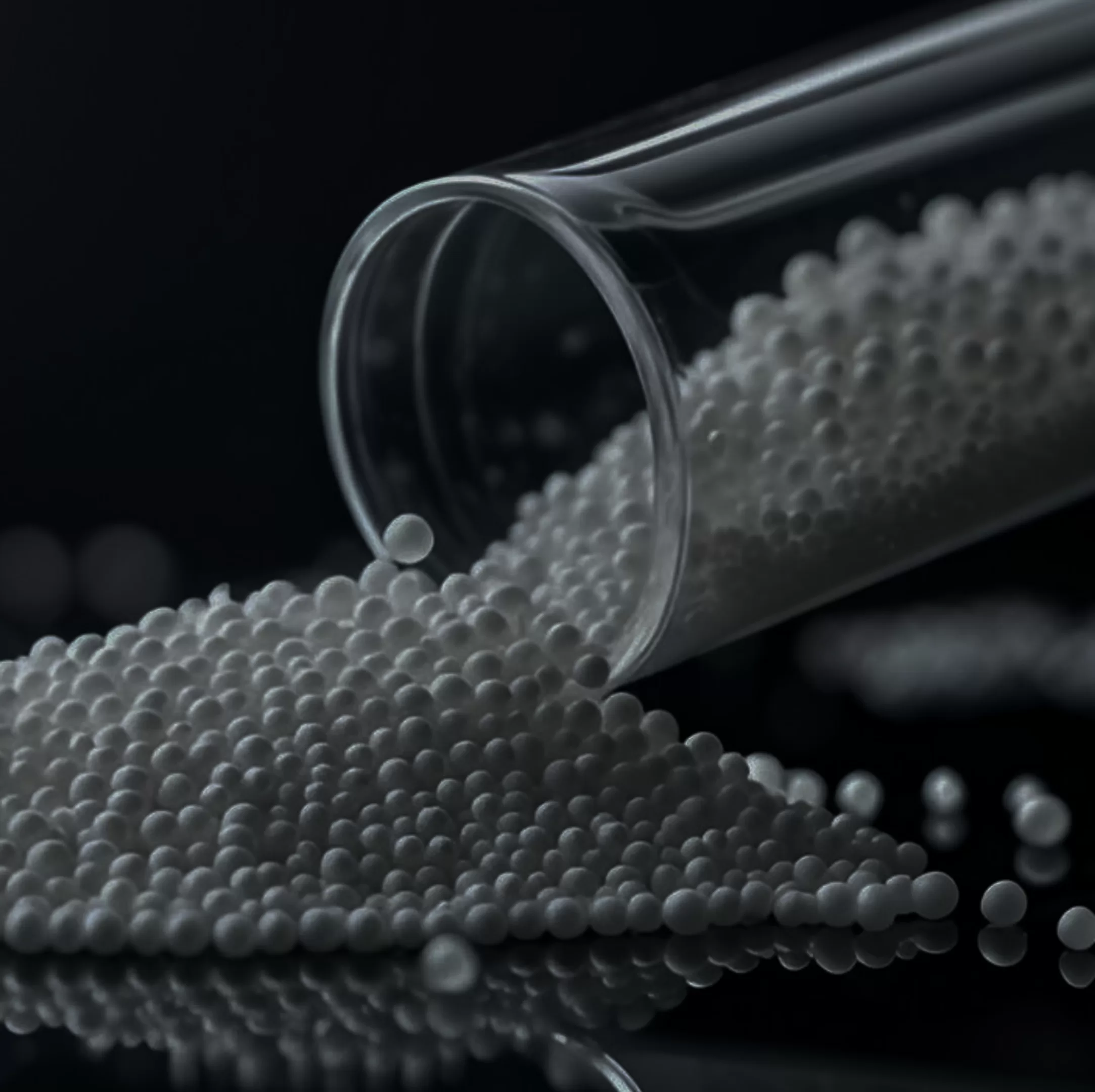

Polymer Evaluation:

Polymers and composites play a vital role in lightweight, high-performance products. In this service, a Materials Engineer evaluates chemical resistance, flexibility, aging, and processability to ensure the chosen materials are up to the task. These evaluations are essential for applications in electronics, automotive interiors, and consumer goods.

Corrosion Assessment:

Environmental degradation can severely reduce the lifespan of materials. Through salt spray testing, electrochemical analysis, and protective coating recommendations, this service identifies vulnerabilities and provides mitigation strategies. A skilled Materials Engineer interprets results to develop long-term corrosion solutions for infrastructure, pipelines, and marine equipment.

Property Testing:

Before a material can be approved for use, it must pass rigorous testing for strength, elasticity, fatigue, and thermal behavior. Clients rely on property testing to validate simulations and meet regulatory demands. These evaluations are conducted and interpreted by a Materials Engineer, who ensures accuracy and relevance to real-world conditions.

Additive Support:

As additive manufacturing continues to grow, so does the need for precision in material performance. From powder flowability to post-processing outcomes, a Materials Engineer helps manufacturers ensure consistency, structural integrity, and repeatability in 3D-printed components—whether for prototyping or end-use production.

All Projects:

At Sydub Engineering Firm, we offer a comprehensive range of materials engineering services to support projects of all sizes and complexities. Whether you're launching a new product, investigating a failure, or optimizing material performance for extreme environments, our team is equipped to deliver expert guidance and technical solutions. Every project is overseen by an experienced Materials Engineer, ensuring that our recommendations are grounded in science, industry standards, and real world performance. From metals and polymers to ceramics and composites, we bring the full strength of materials science to every challenge across industries, applications, and innovation goals.

Materials Engineer Mission:

At Sydub Engineering, our mission is to deliver innovative and reliable solutions by harnessing the expertise of our dedicated Materials Engineer team. We are committed to pushing the boundaries of technology, embracing challenges, and developing systems that drive progress and efficiency. Our engineering team brings together a wealth of experience, collaborating seamlessly to craft solutions tailored to meet the unique needs of our clients. By focusing on precision, creativity, and adaptability, we aim to set new standards in engineering excellence while fostering a culture of continuous learning and innovation.

Stay Connected With Our Materials Engineer Team:

At Sydub Engineering, staying connected with our customers is at the heart of everything we do. We believe that consistent communication and transparency are essential for building trust and delivering exceptional results. Our Materials Engineer team keeps clients informed every step of the way, providing regular updates on progress, key milestones, and innovative solutions as they unfold. Whether it’s through detailed reports, collaborative platforms, or personalized check-ins, we ensure our customers remain fully engaged and up-to-date with the advancements we make together. By fostering strong relationships and maintaining open lines of communication, we empower our clients to confidently navigate the future with the solutions we create.

Materials Engineer Quality Control:

At Sydub Engineering, quality control is not just a process—it’s a promise. Our Materials Engineer team is dedicated to delivering solutions that meet the highest standards of performance, reliability, and precision. Every project undergoes rigorous testing and review, ensuring that each component aligns with industry best practices and our clients’ unique requirements. From initial design to final deployment, our engineering team employs meticulous attention to detail and state-of-the-art tools to identify and address potential issues before they arise. At Sydub, quality is the foundation of trust, and we are committed to exceeding expectations through unparalleled excellence in every solution we deliver.

Stay Connected

Engineering Mission

Quality Gurantee